In April this year, CASE presented its latest introduction – the new CX220C LC-HD 22-ton excavator. This model, manufactured at the manufacturing plant in India, received a number of useful design changes. The letters “HD” in the name of the new excavator indicate the heavy-duty undercarriage design and operating equipment. For example, the turning plate is now solid, new idler guards are in place, the arm plate is thicker by one third: 16 mm compared to the previous 12 mm. The boom of the CX220C LC-HD is 5,7 m long, the bucket volume is 1,1 m³, and the arm is 2,94 m long. The letters “LC” in the model name stand for longer carriage, which now features eight track rollers and triple grouser shoes.

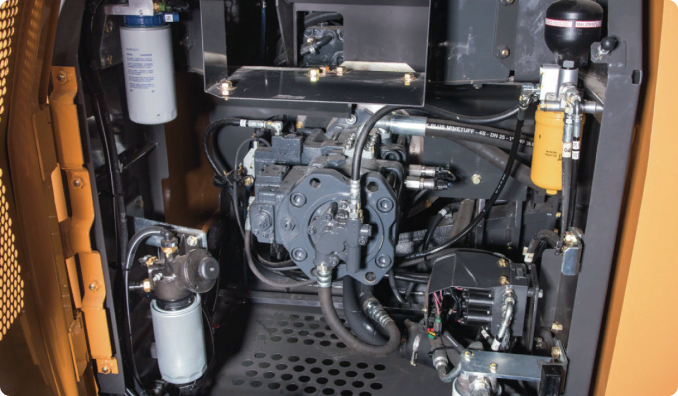

The new excavator is equipped with a new powerful 6-cylinder FPT Tier III 6,7 l engine with a Common Rail electronic control system. The diesel engine power output reaches 157 hp/117 kW, with 622 Nm torque at 1800 rpm. Fuel consumption is reduced by up to 8% by the CASE electronically controlled intelligent hydraulic system, which has five energy-saving automatic functions. The total flow from the two axial piston pumps reaches 422 l/min.

The 30-ton CASE CX300C excavator, similar to other C series models, is manufactured in Japan. Standard excavators are equipped with a 6-cylinder 7,79-liter Tier III engine with Common Rail electronic control system. The rated power of the engine (ISO) at 2000 rpm is 284 hp, the maximum torque at 1500 rpm — 1020 Nm.

5 fuel-saving automatic functions are available, reducing fuel consumption by up to 8%:

CASE engineers have strengthened the model’s operating equipment design for heavy-duty applications (increasing the thickness of materials in higher stress elements) and the bucket linkage. The undercarriage of the CASE CX300C has also undergone changes: thicker hydraulic motor guard plates, increased idler diameter, improved protection of key turntable links.

CASE 865B motor graders offer high acceleration capabilities at all rpms, improved cold start features, and reduced noise levels. The unique “A” frame of these models ensures the robustness and stability of the moldboard and circle. These graders will deliver higher productivity with excellent visibility and best-in-class serviceability.

This is the only CASE Construction Equipment model with 3 engine power curves to create a wide maximum torque range. Switching between curves is automatic – the machine adjusts to operating modes on its own.

Operators of the graders highlight:

A powerful model with high breakout force (242 kN), dump height up to 4,443 m, and bucket capacity of up to 4,8 m³. The cab provides all-round visibility, AC, radio, comfortable and functional controls. The wheel loader’s operating weight stands at 27, 007 tons. The torque reaches 1604 Nm at 1100 rpm. The CASE 1121F is equipped with a 6-cylinder, 347-hp, 8,7-liter FPT engine, compliant with Tier III emissions standard.

The standard models feature:

Options available for customers include a rearview camera, extended boom, L3–L5 tires (L3 being the standard specification). An optional hydraulics line extends the range of attachments.